The roof of a commercial building plays a critical role in protecting a building’s structure and its contents, as well as safeguarding the wellbeing of occupants. Commercial roof maintenance helps to ensure the long-term integrity and functionality of the roof, reducing the risk of leaks, water damage and structural deterioration. Maintenance can also prolong the lifespan of the structure, minimise repair costs and support business continuity.

So what is involved in a commercial roof maintenance regime and how can you take steps to ensure a commercial roof is being adequately maintained? Let’s take an in-depth look at what is required, what can be expected and how a maintenance plan can extend the life of a commercial roof.

What is the life expectancy of a commercial roof?

Depending on factors such as the roof build-up, the quality of installation and the local climate conditions, the life expectancy of a commercial roof can range from 10 to 60 years. With regular inspections, suitable maintenance and timely roof repairs, the expected lifespan of a commercial roof can be extended significantly.

What types of roof maintenance are typically required?

The maintenance needed for a commercial roof will depend on the type of roof in question, but all roofs will require regular cleaning to remove debris, dirt and organic growth from the roof surface and drainage channels. Inspections should also be carried out at least twice a year to check for signs of damage or deterioration.

A commercial roof maintenance plan should also include:

- Checking the roof covering for cracks, bumps or loose edges.

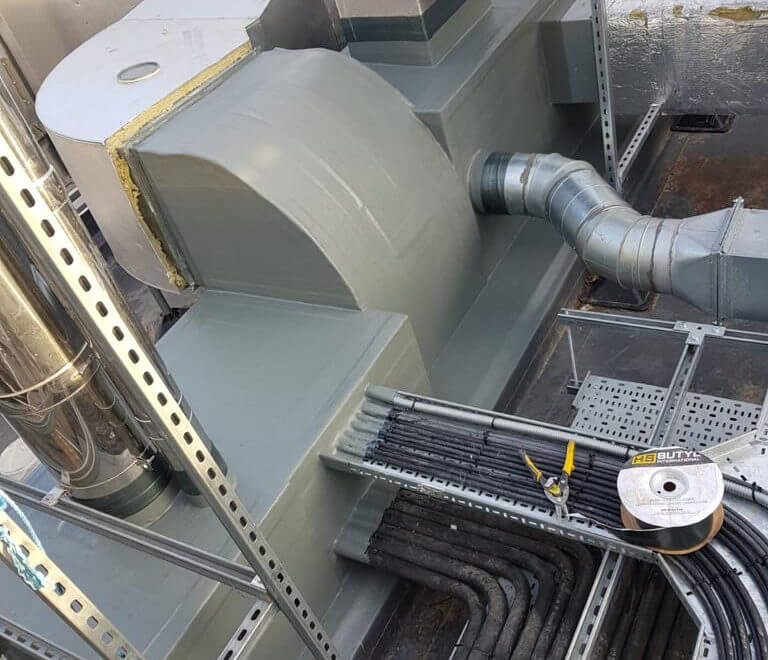

- Inspecting seals, flashings, upstands and curbs around roof penetrations such as chimneys, vents, access hatches and rooflights.

- Inspecting rooftop equipment such as solar panels and HVAC plant to ensure they are in good working order, well supported and secured in place.

- Checking the condition of guardrails, anchor points, walkways and other safety features.

Problems found during routine inspections can often be dealt with quickly and easily before they become bigger issues. For example, Jones and Woolman UK’s cold-applied liquid GRP waterproofing can enhance the durability and weather resistance of a commercial roof with minimal disruption.

It’s important to keep detailed records of all maintenance that is carried out, as well as findings from inspections. This will help to keep track of the roof’s condition and requirements and provide a useful source of information.

What are the implications of not carrying out commercial roof maintenance?

Proactive commercial roof maintenance is essential for preserving the integrity and weather resistance of the roof, and the entire structure. Filing to maintain and regularly inspect a commercial roof can result in structural and financial consequences as well as safety hazards and potential legal repercussions.

Neglected roofs are prone to leaks, and water ingress can damage the building structure, interior and contents. Leaks can also quickly worsen over time, so it’s important to catch leaks early and repair them quickly. Common problems that are caused by inadequate roof maintenance include:

- Structural damage – Water infiltration can compromise a building’s structural integrity, including the roof structure, walls and even the foundations. This can lead to safety hazards or potentially catastrophic failure of the building.

- Damp, mould and mildew – If water permeates the building, it can lead to the growth of mould and mildew, which can damage building materials and cause health risks to occupants.

- Safety hazards – Leaking roofs can lead to wet, slippery floors, or allow water to get into machinery, which could endanger operators. If the rooftop is used for access, damage to the roof surface can also create trip hazards or other safety risks.

- Damage to building contents – From factories and warehouses to offices, shops and restaurants, commercial buildings are full of contents that are necessary for business continuity and expensive to replace.

- Decreased energy efficiency – Cracks, gaps and other commercial roof damage cause draughts and cold bridges, leading to heat loss in the winter or heat gain in summer. HVAC systems will then need to work harder to maintain indoor temperatures, thereby increasing energy consumption and running costs.

The damage caused by inadequate commercial roof maintenance can reduce the property value, as potential tenants or buyers may be deterred from investing in a property that may require extensive repairs.

Neglecting commercial roof maintenance may also lead to other financial or legal implications. For example, the roof systems warranties could become void, meaning the building owner would have to pay the full cost for any necessary repairs or replacements. Safety violations caused by insufficient roof maintenance could lead to legal repercussions, and insurance claims may be denied if roof-related damage is found to have occurred due to poor maintenance.

If you’re not sure what roof maintenance and repairs are required, an expert site survey can help you better understand the current state of your commercial roof.

Extend the life of your commercial roof: maintenance services from Jones and Woolman UK

Regular maintenance is key for ensuring the structure has a long lifespan and performs as expected. This includes roof inspections, cleaning and repairs where needed.

As approved installers of cold-applied liquid waterproofing, Jones and Woolman UK has extensive experience in commercial roof maintenance. Our specially developed cold applied repair solution for GRP roofing systems can be used to repair all types of flat or pitched roofs, and we offer comprehensive maintenance plans to help protect and extend the life of your roof.

To discuss creating a commercial roof maintenance plan for your building please get in touch.