Fulham FC’s football ground, also known as Craven Cottage, has recently been transformed with the construction of its new riverside stand. And the team at Jones and Woolman UK have made sure to fully weatherproof every building penetration as well as the roof and on this £80m structure.

Stadium weatherproofing and building penetrations

The impressive development, which backs up to the River Thames, is built on marine piling, extending buildable space into the river and allowing the riverside path to be opened up to pedestrians and cyclists. The stand features two tiers of seating, increasing the stadium’s capacity by 8,650 people. Once completed, it will also serve the broader community with restaurants, events spaces, a boutique hotel and a health club with rooftop pool.

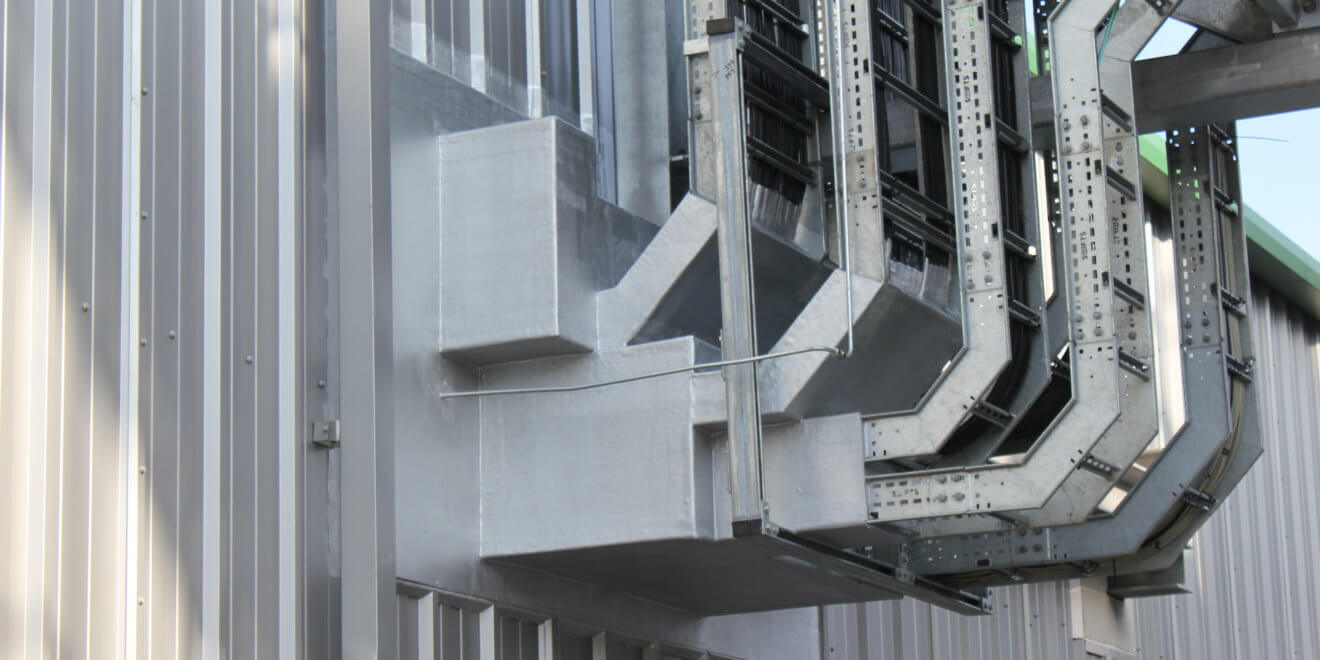

With so much going on inside the Riverside Stand, it’s no surprise that hundreds of building penetrations were required, from water and soil pipes to electrical supplies, HVAC vents and data and communications cables and cable trays. To help make the stand more sustainable, a significant portion of the roof is also covered in solar panels, meaning even more roof penetrations were needed to feed the electricity into the building.

Tom West, project manager at Buckingham Group Contracting Ltd says that Jones and Woolman UK were called in to make sure that the roof was weatherproofed and that all of the vertical penetrations were fully sealed against weather ingress.

“Jones and Woolman UK was recommended by one of my colleagues who worked with them on a previous sports stadium weatherproofing project,” he explains. “He said he was really happy to work with them, and that’s how J&W got involved in the project,” he adds.

Weathering the challenges

Tom explains that this was an extremely complex project, with challenges ranging from the Covid-19 pandemic to industry-wide shortages of labour and materials.

With much of the construction work being carried out from barges on the Thames, he had to organise barges and plan for the tides. Plus, the football stadium was still in regular operation throughout the building programme. Work had to be paused on match days for safety reasons and inspections had to be carried out to ensure that players, team management, the press and ball boys could access the unfinished stand safely.

Tom says that all of these challenges meant that scheduling the weatherproofing work was sometimes difficult. “We had to be reactive to how the project was going, and that sometimes-meant minimal lead times for getting the J&W team out” he explains. It was sometimes tricky, but he liaised with Steve Smith, technical manager at Jones and Woolman UK, on a regular basis and “work was always completed within our time restraints”.

Weatherproofing and building penetration goals

To weatherproof the roof and building penetrations, Jones and Woolman UK had to use a variety of skills and techniques. Through our design and build service, fibreglass service risers, upstands and details were custom-made to fit around the penetrations, and everything was sealed with our GRP cold-applied liquid.

“The result looks great; they’ve done a really professional job,” Tom says, noting that the team dealt with the access issues and other challenges really well. “They’ve had a lot of patience, the guys on site were great to work with, the workmanship is good; I can’t fault them for anything,” he adds.

If you’d like to learn more about our range of weatherproofing and building penetration services or discuss your weatherproofing requirements with a member of our team, please get in touch. You can phone us on 01922 712111 or contact us using the form on this page.